The roar of the engine. The anticipation of raw power. Then—nothing. A split-second of emptiness where pure performance should explode. This is turbo lag, the silent killer of automotive dreams, the moment between intention and acceleration that can transform a potential champion into a frustrated driver. In the high-stakes world of performance engineering, this brief pause represents more than just a technical challenge—it’s a battlefield where precision meets pure mechanical will.

In this article, we’ll break down exactly how anti-lag works, explore its different forms, and dig into the science that makes it all possible. Whether you’re a gearhead, a tuning enthusiast, or just turbo-curious, this deep dive will demystify the magic behind instantaneous boost.

Types of Anti-Lag Systems

Anti-lag comes in several distinct flavors, each with its own pros, cons, and quirks. The major types we’ll cover include:

- Ignition Retardation ALS

- Air Injection ALS

- Fuel Cut ALS

- Combination ALS (a hybrid approach blending multiple techniques)

The Mechanics of Turbo Lag

How a Turbocharger Works

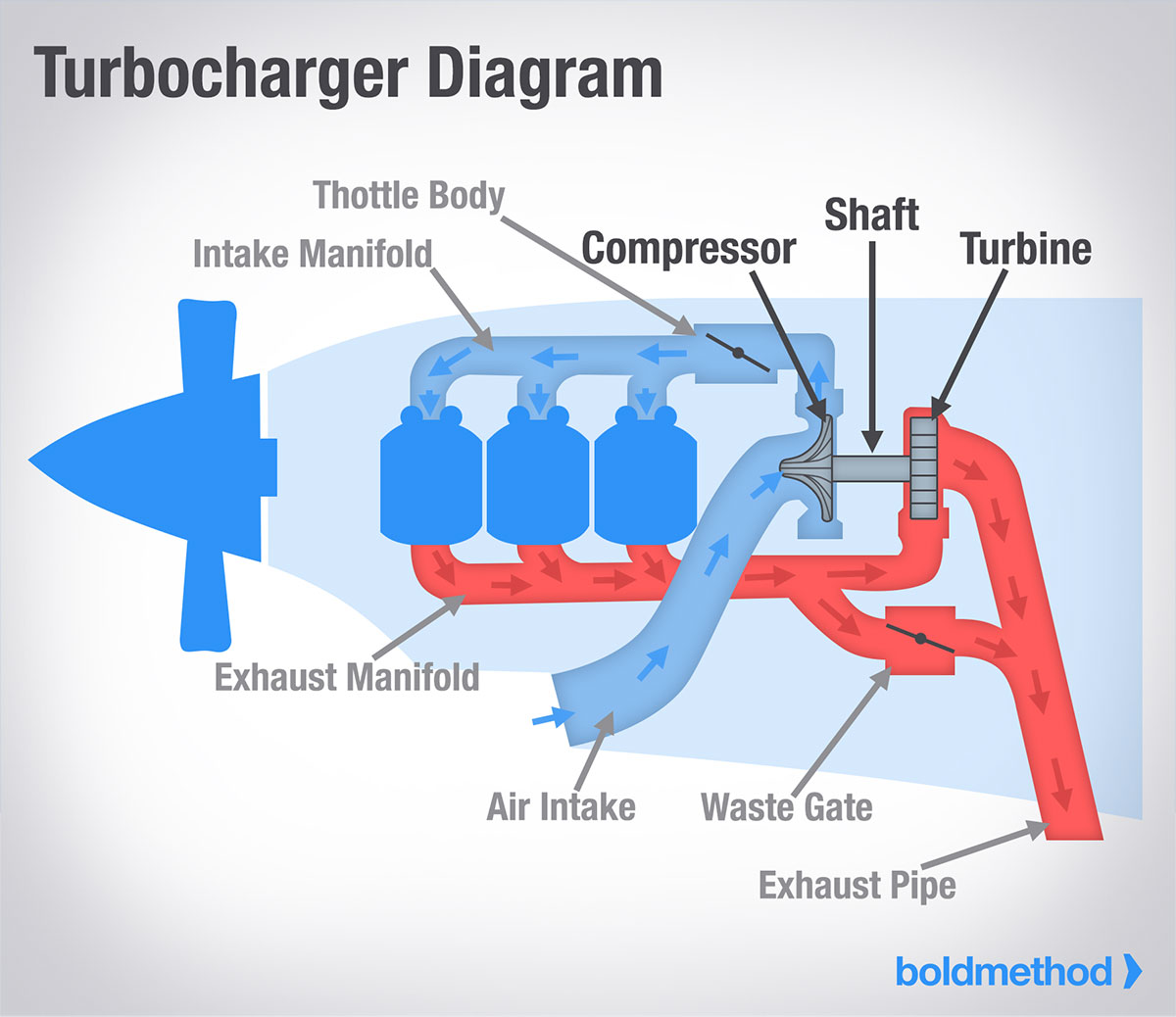

At its core, a turbocharger is an air pump driven by exhaust gases. Hot exhaust spins a turbine wheel, which is connected by a shaft to a compressor wheel. As the turbine spins, the compressor pulls in fresh air, compresses it, and forces it into the engine’s intake. More air means more oxygen, which means more fuel can be burned, producing more power from the same-sized engine.

The Causes of Turbo Lag

Turbo lag happens because the turbine and compressor have inertia—they take time to spin up to speed. This is especially noticeable during:

- Off-throttle situations like cornering, where exhaust flow drops.

- Low RPM driving, when exhaust gas velocity is low.

- Sudden throttle inputs, where the turbo needs to ‘catch up’ to the driver’s demands.

Building boost from low speed requires time—often measured in fractions of a second, but enough to make the difference between winning and losing.

The Impact of Turbo Lag on Driving Experience

For drivers, turbo lag is more than a minor inconvenience—it fundamentally alters how a car behaves:

- Delayed power delivery disrupts throttle response.

- Reduced responsiveness means slower reaction to mid-corner throttle changes.

- Inconsistent power delivery can make driving a turbocharged car unpredictable, especially in motorsport scenarios where precision matters.

The Mechanics of Anti-Lag Systems (ALS)

Basic Principle

The core idea of anti-lag is simple: keep the turbo spinning, even when you’re off the throttle. To do this, ALS introduces a combustible mix of fuel and air into the exhaust manifold, which ignites and produces hot expanding gases that keep the turbine moving. This keeps the turbo on the boil, meaning boost is instantly available the moment the driver gets back on the gas.

Types of Anti-Lag Systems

Ignition Retardation ALS

This is one of the most common systems. When the driver lifts off the throttle, the ECU retards ignition timing drastically—so much so that combustion finishes late, partially inside the exhaust manifold. This produces hot gases that spool the turbo even without much exhaust flow.

Benefits:

- Simple to implement on modern ECUs.

- Effective in maintaining boost.

Drawbacks:

- Very harsh on the turbo and exhaust components due to extreme heat.

- Loud, with lots of pops and bangs (cool for spectators, less so for longevity).

Air Injection ALS

In this system, an external air pump injects fresh air into the exhaust manifold when off-throttle. Combined with injected fuel, this creates a controlled burn that keeps the turbo spinning.

Benefits:

- Less heat-related stress than ignition retardation.

- Can be smoother and quieter if tuned correctly.

Drawbacks:

- More complex due to the need for an air pump and extra plumbing.

- Slightly slower response compared to ignition retard.

Fuel Cut ALS

This method injects fuel even when off-throttle, allowing it to ignite in the hot exhaust stream. This keeps exhaust energy high, spinning the turbo.

Benefits:

- Effective at maintaining boost.

- Less complexity than air injection.

Drawbacks:

- High fuel consumption.

- Can lead to unburnt fuel buildup and catalytic converter damage.

Combination ALS

High-end racing setups often combine methods, blending ignition retard, air injection, and fuel cut to maximize boost retention while minimizing component stress.

Benefits:

- Highly customizable for different driving situations.

- Can balance response with longevity.

Drawbacks:

- Complex to tune.

- Requires extensive data logging and expert calibration.

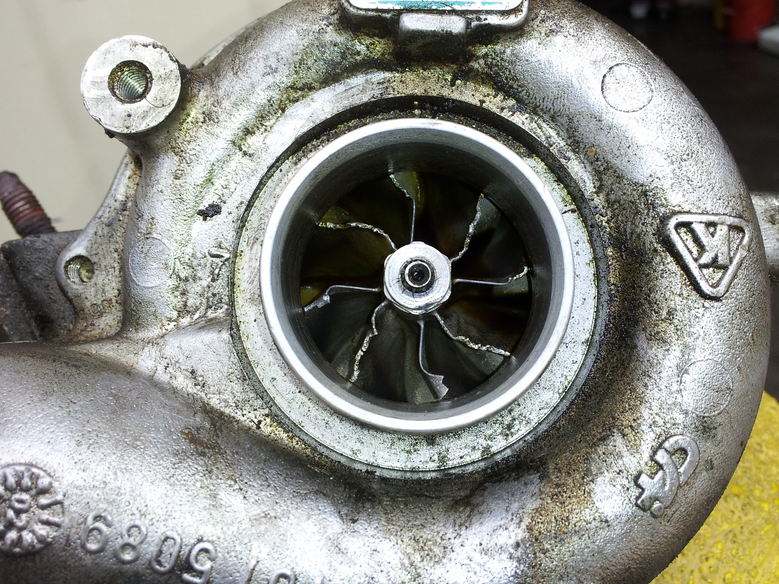

The Combustion Process in the Exhaust Manifold

Regardless of type, ALS relies on controlled combustion happening inside the exhaust manifold rather than the combustion chamber. This process keeps exhaust energy high, but it’s also brutal on exhaust components, especially the turbo itself.

Key considerations include:

- Temperature management to avoid overheating.

- Material selection for turbo housings, manifolds, and exhaust piping.

- Careful tuning to avoid uncontrolled detonation.

Control Systems and Tuning

Modern ALS is managed by the ECU, which monitors throttle position, RPM, exhaust temperature, and boost pressure to decide when and how to engage anti-lag.

Proper tuning is absolutely critical. Poorly tuned ALS can destroy turbos, crack exhaust manifolds, and even cause catastrophic engine failure. Professional race teams spend countless hours on dynos and in simulation tweaking ALS maps for optimal balance between performance and reliability.

Benefits of Anti-Lag Systems

Reduced Turbo Lag

At its core, the anti-lag system exists to erase the agonizing pause between throttle application and turbo spool — and it does so with remarkable effectiveness. In a properly set-up ALS, the time needed to build full boost pressure can shrink from seconds to mere milliseconds. In rally applications, this could mean maintaining nearly full boost even while off-throttle, ensuring explosive acceleration the moment the driver gets back on the gas.

Improved Throttle Response

Throttle response is the unsung hero of driving feel. A vehicle equipped with ALS responds almost telepathically to throttle inputs, with the turbo already primed and spinning. Whether exiting a hairpin turn or preparing for a high-speed straightaway, ALS ensures there’s no sluggish pause — just instant, violent forward motion.

Enhanced Performance in Racing and Performance Driving

In motorsport, fractions of a second can be the difference between victory and defeat. Anti-lag gives race cars an edge in scenarios where rapid throttle modulation is essential — like in rally stages with tight corners or in time attack events where every transition matters. With boost pressure sustained through every lift-off and gear change, drivers can push harder, knowing the power will be there exactly when needed.

Maintaining Boost Pressure

Without ALS, turbo boost pressure can drop significantly during deceleration or cornering. Once the driver reapplies throttle, the turbo has to play catch-up. ALS sidesteps this problem entirely, keeping the turbo spinning at near-optimal speeds at all times. The result? Seamless transitions, relentless acceleration, and a driving experience that feels constantly “on boost.”

Drawbacks and Considerations

Increased Exhaust Manifold Temperatures

All that combustion happening directly inside the exhaust system comes at a cost — intense heat. Exhaust manifolds and turbine housings face extreme thermal stress, with temperatures soaring well beyond what they experience in a conventional turbo setup. This necessitates heat shielding, high-temp coatings, and robust materials designed to withstand this brutal environment.

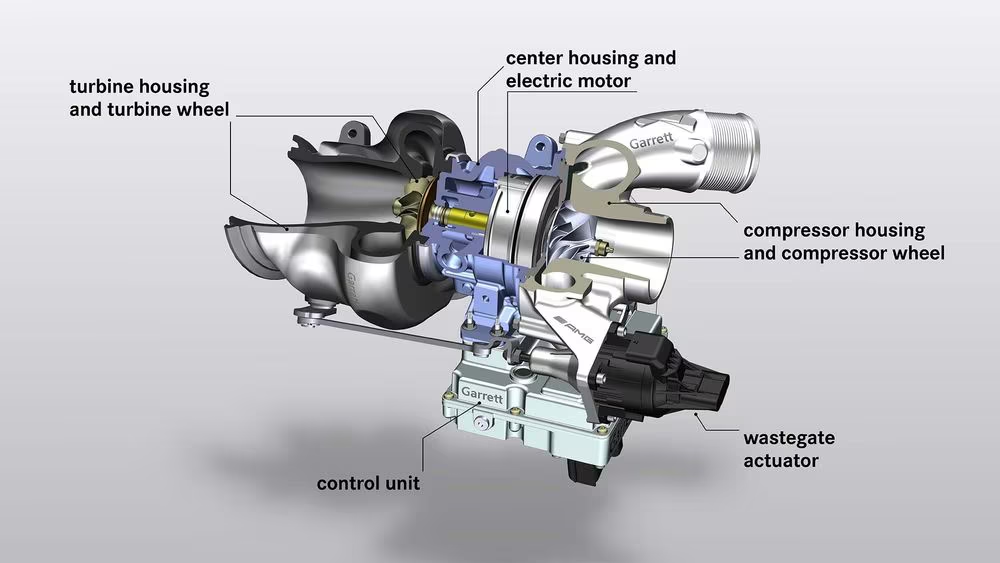

Potential for Turbocharger Damage

Turbochargers are finely balanced, precision components — and ALS puts them through hell. The continuous bursts of combustion in the exhaust can cause excessive shaft speeds, mechanical stress, and thermal fatigue. In poorly tuned systems, this can lead to catastrophic turbo failure, leaving drivers with little more than molten metal and regret.

Increased Fuel Consumption

Keeping the turbo spinning means keeping the fire lit, even when the throttle is closed. This constant fuel and air injection into the exhaust, while excellent for boost, is a nightmare for fuel economy. ALS-equipped cars guzzle fuel like it’s going out of style, making them ill-suited for daily drivers with an eye on MPG.

Noise and Emissions

The signature pops, bangs, and flames of ALS-equipped cars are music to the ears of performance enthusiasts — but they’re also a red flag for emissions regulators. The unburnt fuel igniting in the exhaust creates excessive hydrocarbons, making these systems extremely unfriendly to emissions standards. In street applications, this often leads to legal headaches, especially in regions with strict environmental laws.

Complexity and Cost

Implementing ALS isn’t just a bolt-on affair. It requires substantial investment in hardware (such as upgraded ECUs, sensors, injectors, and reinforced exhaust components) and professional tuning expertise. For enthusiasts seeking that last tenth of a second, the cost may be justified — but for the average driver, it’s a steep price to pay for explosive performance.

Implementation and Tuning

Hardware Requirements

A successful ALS setup starts with the right hardware. This typically includes a programmable ECU capable of controlling ignition timing, air injection, or fuel delivery under off-throttle conditions. Depending on the chosen type of ALS, additional components like external air pumps or specialized injectors may be required. Reinforced exhaust components capable of surviving constant thermal shock are also mandatory.

Tuning and Calibration

Tuning an ALS system is more art than science — and getting it wrong can spell disaster. Professional tuners adjust ignition timing, fuel delivery, air injection rates, and target turbo speeds to strike a delicate balance between performance, reliability, and thermal management. Datalogging is critical, allowing tuners to monitor temperatures, pressures, and component stress in real-time. This isn’t a set-it-and-forget-it affair; ongoing refinement is necessary to keep the system healthy.

Safety Precautions

ALS, in the wrong hands, can turn a high-performance machine into a scrapyard candidate in minutes. Careful monitoring of exhaust temperatures, turbo speeds, and air/fuel ratios is essential to prevent runaway heat, detonation, or mechanical failure. In competition settings, teams often employ thermal cameras or specialized sensors to detect hot spots before they escalate into failures.

Real-World Applications

Motorsport Examples

Anti-lag is a staple in modern rally racing, where cars constantly transition between full throttle and heavy braking on tight, technical stages. WRC (World Rally Championship) cars, in particular, rely heavily on ALS to maintain explosive power delivery across varied terrain. In circuit racing, certain time attack and endurance builds also incorporate ALS to maintain consistent power delivery in tight corner sequences.

Performance Street Cars

While rare, ALS occasionally finds its way into heavily modified street cars — usually in the hands of hardcore enthusiasts willing to sacrifice comfort, noise levels, and fuel economy for pure performance. Some high-end tuner builds (particularly in the JDM and European performance scenes) experiment with mild ALS setups designed to offer better spool without totally compromising street manners.

Demonstrations and Videos

Nothing captures the drama of anti-lag better than a good video. The sight of a rally car exiting a corner, exhaust glowing red-hot, with machine-gun pops echoing through the forest, is motorsport magic. For those curious, YouTube is a treasure trove of ALS compilations — from Group B monsters to modern WRC rockets, the spectacle is mesmerizing.

Conclusion

Anti-lag systems are both a blessing and a curse — a technical marvel capable of transforming turbocharged performance, but at the cost of heat, noise, fuel, and complexity. By keeping the turbo spinning during off-throttle moments, ALS provides instant boost and razor-sharp throttle response, making it indispensable in competitive motorsport.

As turbo technology advances, the future of ALS may shift. Electrically assisted turbos (e-turbos) already offer lightning-fast spool without the need for explosive anti-lag techniques. However, for the foreseeable future, pure mechanical ALS remains king in high-stakes racing environments where every millisecond counts. Perhaps future hybrid ALS systems will combine electric assist with traditional anti-lag to offer the best of both worlds.

For those chasing ultimate turbo performance, anti-lag is a seductive — albeit brutal — solution. It’s not for the faint-hearted or the budget-conscious, but for those who live for crackling exhausts, instant boost, and the relentless pursuit of speed, ALS is an irresistible piece of automotive witchcraft. Turbo lag may be an age-old problem, but with anti-lag, the wait is finally over.