Did you know that every 10-degree increase in oil temperature can significantly shorten an engine’s lifespan? In high-performance applications—whether track racing, off-roading, or towing—engine temperatures can skyrocket, leading to premature wear and even catastrophic failures. Oil plays a critical role in keeping internal components lubricated and reducing friction, but excessive heat can compromise its effectiveness.

Most vehicles rely on standard oil-to-water heat exchangers, which transfer heat from the oil to the engine’s coolant system. While effective in daily driving scenarios, these systems have limitations in extreme conditions. They struggle to dissipate the additional heat generated during prolonged high-load operation, which can lead to oil thinning, increased wear, and power loss.

For high-performance applications, custom oil cooling solutions provide a significant advantage by maintaining optimal oil temperatures under extreme stress. This article delves into advanced oil cooling techniques that go beyond factory setups, ensuring peak engine performance and longevity.

The Importance of Oil Temperature Management

Oil Viscosity and Performance

Oil viscosity is critical to engine protection. When oil gets too hot, it thins out, reducing its ability to properly lubricate engine components. This leads to increased metal-on-metal contact, higher friction, and accelerated wear. Maintaining an optimal oil temperature ensures that viscosity remains stable, allowing for consistent performance and reduced engine strain.

Engine Component Degradation

Excessive oil temperatures can severely impact critical engine parts such as bearings, pistons, and camshafts. Bearings rely on a thin oil film to prevent direct metal contact. If the oil overheats and loses viscosity, the protective film weakens, increasing friction and the risk of failure. Similarly, pistons and cylinder walls depend on adequate lubrication to reduce wear. Without it, scoring and excessive heat buildup can occur, leading to reduced efficiency and costly repairs.

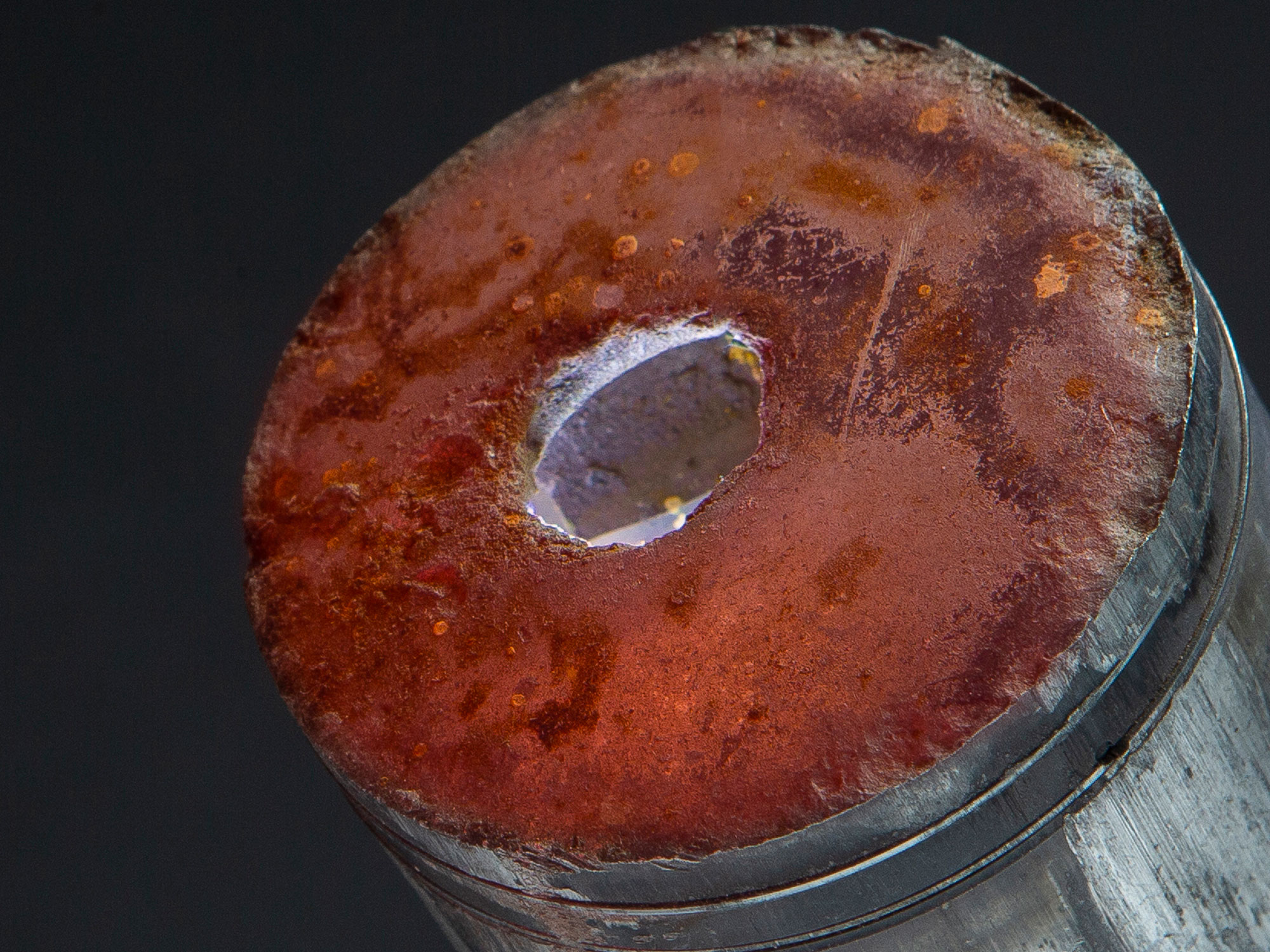

Oil Oxidation and Breakdown

Heat accelerates oil oxidation, causing it to degrade and form sludge and deposits. Oxidized oil loses its lubricating properties, increasing engine wear and reducing performance. This is especially problematic in turbocharged and high-compression engines, where oil temperatures can quickly exceed safe limits. By managing oil temperatures effectively, oxidation is minimized, extending oil life and preserving engine health.

Performance and Efficiency

Maintaining proper oil temperature doesn’t just protect the engine—it also enhances performance and fuel efficiency. Excessive heat increases internal friction, which saps power and forces the engine to work harder. A well-regulated oil cooling system ensures that oil remains within the optimal temperature range, allowing for smooth power delivery, improved throttle response, and reduced energy loss due to heat buildup.

Scenarios Where Standard Oil Cooling Fails

Standard oil cooling systems struggle in extreme conditions. In high-performance track use, continuous high RPMs and heavy loads cause oil temperatures to rise beyond safe levels. Similarly, vehicles towing heavy loads experience prolonged stress, leading to overheating. Off-road vehicles operating in hot climates face additional challenges, as limited airflow and slow speeds reduce cooling efficiency. In these situations, advanced oil cooling solutions become essential.

Advanced Oil Cooling Solutions

To address the limitations of standard cooling systems, advanced oil cooling solutions are essential. These custom setups offer superior temperature management, ensuring optimal engine health and performance.

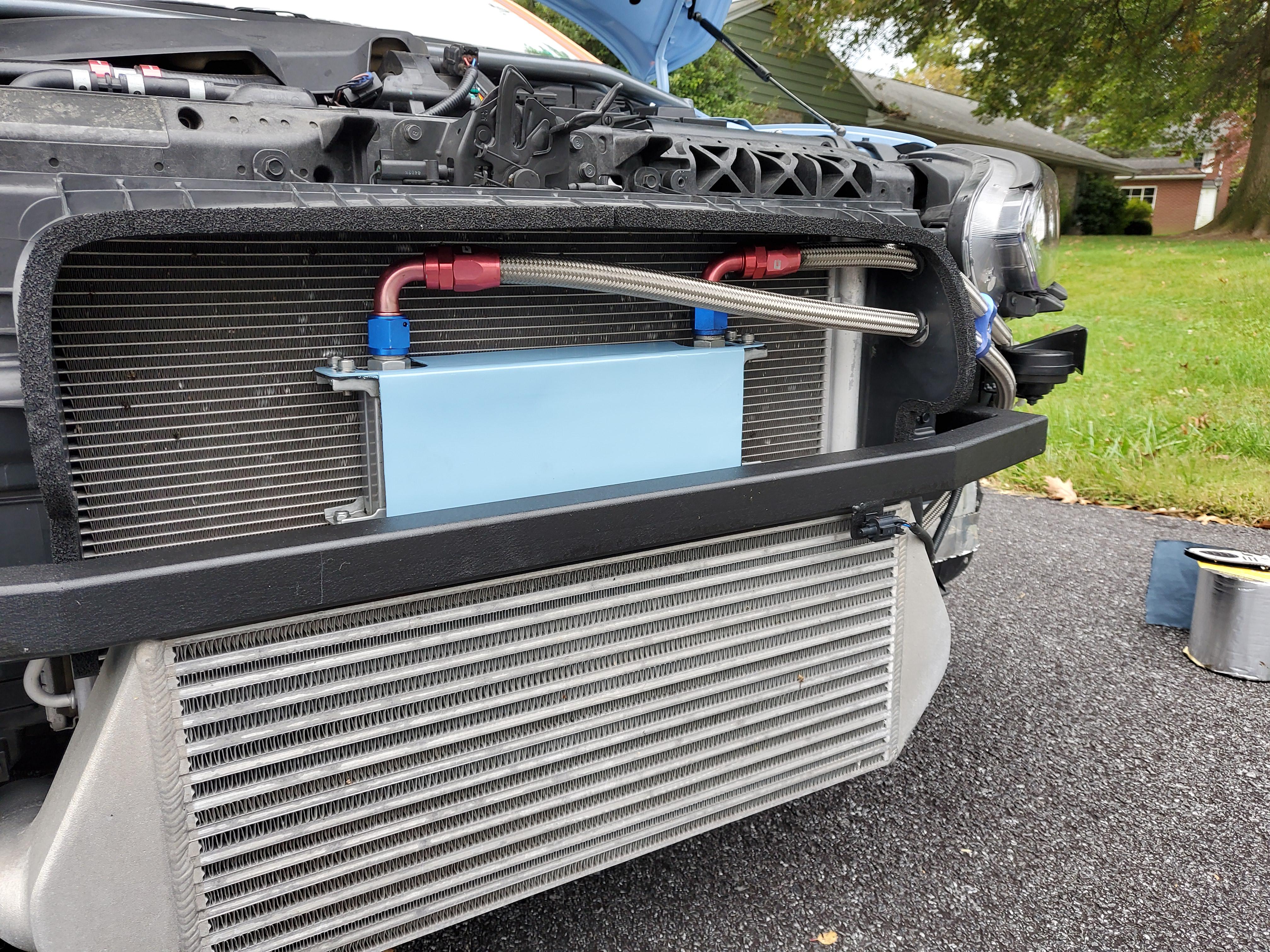

External Oil Coolers

- Types: Air-to-oil coolers use airflow to dissipate heat, while oil-to-water coolers leverage engine coolant for temperature control.

- Sizing and Placement: The size of the cooler must match the engine’s oil flow rate and heat dissipation needs. Mounting in high-airflow areas (e.g., front grille) maximizes cooling efficiency.

- Core Design: Stacked plate coolers provide the best heat dissipation, while tube-and-fin designs are more compact but less efficient.

- Benefits: Improved cooling capacity reduces engine bay temperatures, enhancing overall thermal efficiency.

Remote Oil Filter Systems

- Benefits: Relocating the oil filter simplifies oil changes, increases oil capacity, and enhances filtration.

- Types: Single filter setups are common, while dual filter systems offer increased filtration capacity.

- Integration with Oil Coolers: Remote filters can be paired with external coolers to further improve oil temperature regulation.

Thermostatic Oil Sandwich Plates

- Function: These plates regulate oil flow to the cooler based on temperature, ensuring oil reaches operating temperature before cooling is engaged.

- Benefits: Faster warm-up times, consistent oil temperatures, and reduced engine wear.

- Types: Internal thermostats are built into the plate, while external thermostats provide greater flexibility in setup.

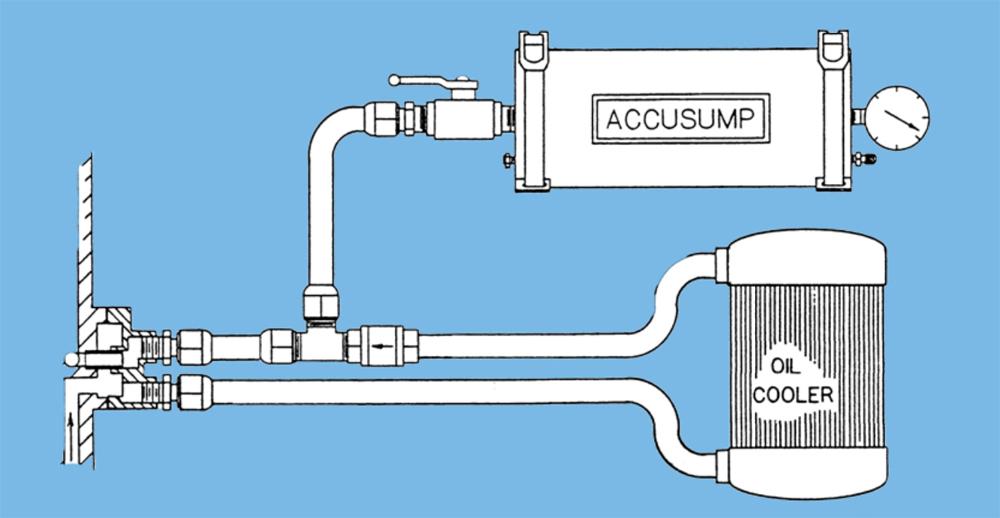

Oil Accumulator Systems

- Function: These systems store and release pressurized oil during high-G maneuvers, preventing oil starvation in performance applications.

- Applications: Essential for track racing, off-roading, and other extreme driving conditions.

- Benefits: Enhanced engine protection, improved oil pressure stability, and extended component lifespan.

Custom Oil Pan Modifications

- Baffling: Internal baffles prevent oil from sloshing during aggressive acceleration, braking, and cornering.

- Increased Capacity: Larger oil pans allow for more oil volume, improving cooling and lubrication.

- Integrated Cooling Fins: External fins on the oil pan enhance heat dissipation, further regulating temperature.

Oil Spray Bars

- Function: These systems spray oil onto the underside of pistons, lowering piston crown temperatures and reducing detonation risk.

- Applications: Common in turbocharged and high-compression engines, where internal temperatures are significantly higher.

- Benefits: Improved engine longevity, reduced knock, and enhanced reliability under high-performance conditions.

Application-Specific Considerations

Advanced oil cooling solutions must be tailored to specific driving conditions and performance demands. Each application—whether track racing, off-roading, towing, or high-performance street driving—presents unique challenges that require specialized solutions.

Track Racing & Off-Roading

Track cars operate under extreme stress, with sustained high RPMs and aggressive acceleration, braking, and cornering. High-G forces can lead to oil starvation, making advanced oil cooling essential. Proper cooler placement, often in high-airflow areas with ducting, helps prevent heat soak from surrounding components. Data logging and real-time oil temperature monitoring allow racers to fine-tune cooling efficiency, ensuring consistent performance throughout a race.

Off-road environments introduce additional challenges, including extreme ambient temperatures and debris exposure. External oil coolers must be protected from rocks and mud, often requiring grille covers and skid plates. Engine oil pans with baffles and reinforced construction help maintain lubrication on steep inclines or uneven terrain. Since airflow can be limited at low speeds, some off-road setups integrate forced cooling fans for consistent temperature regulation.

Towing & High-Performance Street Cars

Towing-heavy loads places immense strain on an engine, leading to prolonged heat buildup. High-capacity oil coolers and increased oil volume help manage heat, while separate transmission coolers prevent overheating in automatic vehicles. These setups are essential for ensuring reliability and extending engine and transmission lifespan under heavy-duty conditions.

For high-performance street cars, oil cooling must balance efficiency with practicality. Since most daily-driven vehicles lack space for large external coolers, compact, efficient designs are often used. Thermostatic control helps regulate oil temperatures, ensuring the system engages only when necessary, preventing overcooling during normal driving. Additionally, noise considerations come into play, as some fan-driven oil coolers may produce unwanted sound in a daily-driven vehicle.

Installation and Maintenance

While some enthusiasts may opt for a DIY installation, professional installation ensures proper routing, secure fittings, and integration with the engine’s oil flow system. Incorrect installation can lead to leaks, pressure loss, or inefficient cooling. High-quality heat-resistant hoses and AN fittings should be used to withstand extreme temperatures and pressures.

Regular maintenance is crucial for long-term performance. Oil coolers should be inspected and cleaned periodically to prevent dirt buildup that can reduce efficiency. Mounting brackets must be checked to avoid vibrations that could lead to leaks or damage. Additionally, selecting the correct oil viscosity and type plays a crucial role in maintaining optimal lubrication and thermal stability.

Conclusion

Custom oil cooling solutions enhance engine protection, prevent oil breakdown, and improve overall performance. Whether for track use, off-roading, towing, or daily driving, an optimized cooling system helps maintain reliability under stress.

No single solution works for every vehicle—each application requires a tailored approach. The right setup depends on factors like driving conditions, available space, and specific cooling needs.

Before upgrading an oil cooling system, enthusiasts should consult experts, research available options, and analyze vehicle-specific requirements to maximize efficiency.