When it comes to engine performance and longevity, few topics are as critical—and misunderstood—as knock. Whether you’re a casual driver, a racing enthusiast, or a professional tuner, understanding knock is essential to preventing costly engine damage and optimizing power output. Knock is not just a minor nuisance; it’s a serious problem that can lead to catastrophic failure if left unchecked.

Knock is an abnormal combustion event that disrupts the normal combustion process. The two primary types of knock are detonation and pre-ignition, both of which can cause severe damage to an engine. While these terms are sometimes used interchangeably, they refer to distinct phenomena that require different preventive measures.

Recognizing the differences between detonation and pre-ignition is crucial for safe and effective engine tuning.

The Fundamentals of Combustion

Normal Combustion

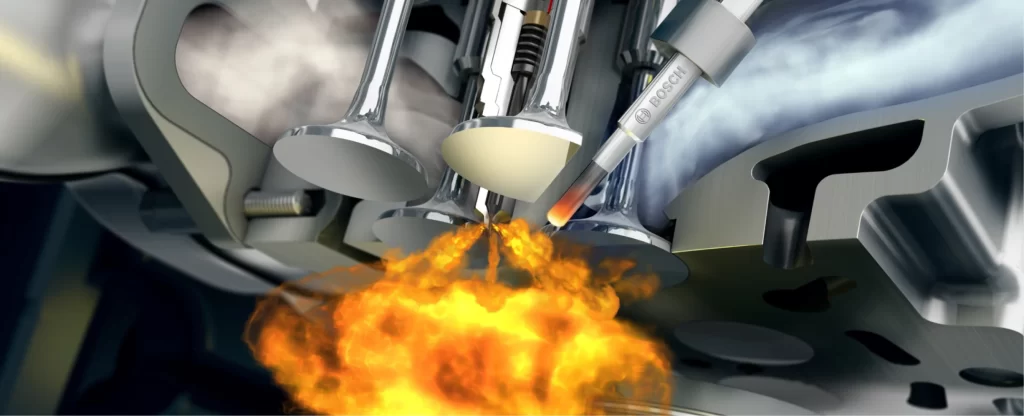

In an optimally functioning gasoline engine, combustion follows a controlled and predictable sequence:

- The spark plug ignites the fuel-air mixture at precisely the right moment.

- The flame front propagates smoothly from the ignition source, burning the mixture evenly.

- The controlled combustion pushes the piston down, converting chemical energy into mechanical work.

The effectiveness of this process depends on proper spark timing, fuel mixture, and air-fuel ratio. Any deviation from this ideal sequence can lead to abnormal combustion events like knock.

Abnormal Combustion

Abnormal combustion occurs when the controlled flame front is disrupted, leading to either detonation or pre-ignition:

- Detonation: The spontaneous ignition of remaining fuel-air pockets, resulting in sharp pressure spikes.

- Pre-ignition: The premature ignition of the fuel-air mixture before the spark plug fires, leading to uncontrolled combustion.

Understanding these differences is key to diagnosing and preventing engine knock.

Detonation (Knock)

Detonation is an uncontrolled, supersonic combustion event that occurs after the normal spark-initiated ignition. Instead of a smooth flame front, pockets of fuel ignite spontaneously, producing shockwaves that create damaging pressure spikes within the combustion chamber.

Causes of Detonation

1. High Cylinder Temperatures

- Increased compression ratios, high boost pressures, and lean air-fuel mixtures raise cylinder temperatures, increasing the likelihood of detonation.

- Heat soak from engine components and inadequate cooling systems exacerbate the problem.

2. Incorrect Spark Timing

- Advancing the spark too much causes the fuel-air mixture to ignite too early, leading to excessive cylinder pressure and detonation.

- Tuners must carefully balance ignition timing to maximize performance without causing knock.

3. Low Octane Fuel

- The octane rating of gasoline determines its resistance to knock. Lower-octane fuels ignite more easily under pressure, making them more susceptible to detonation.

- High-performance engines require higher-octane fuel to prevent knock and maintain efficiency.

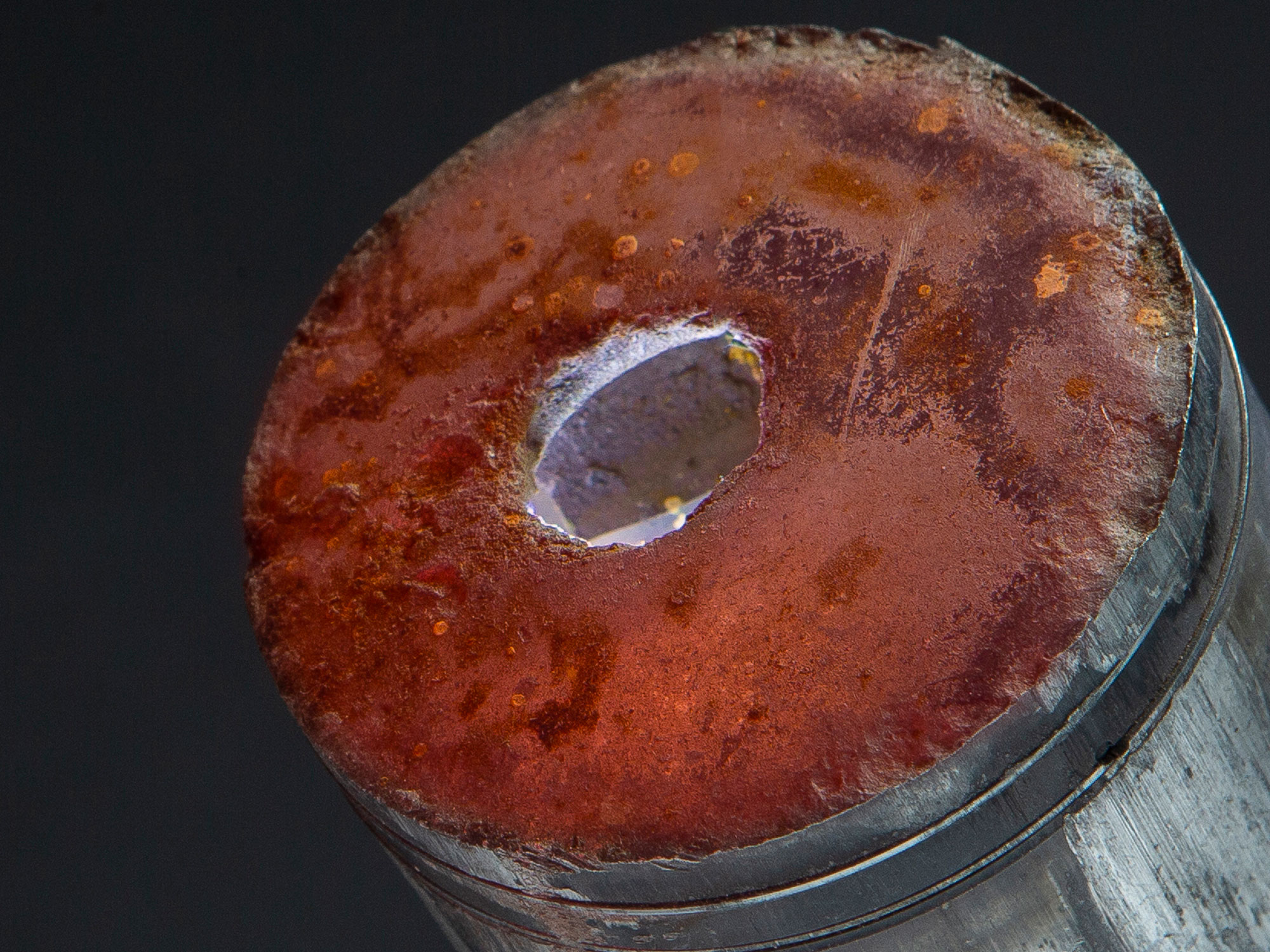

4. Hot Spots

- Carbon deposits, overheated spark plugs, and sharp edges in the combustion chamber can create localized hot spots that ignite the fuel prematurely, leading to detonation.

- Regular maintenance and carbon-cleaning treatments help minimize these risks.

Effects of Detonation

1. Engine Damage

- The repeated pressure spikes from detonation can crack pistons, break ring lands, and cause bearing failures.

- Severe cases can even result in complete engine failure.

2. Power Loss

- When detonation disrupts normal combustion, the engine loses efficiency and produces less power.

- Tuners often reduce ignition timing to avoid knock, sacrificing performance in the process.

3. Increased Engine Noise

- One of the most recognizable symptoms of detonation is a metallic “pinging” or “knocking” sound.

- This noise results from the violent shockwaves inside the combustion chamber.

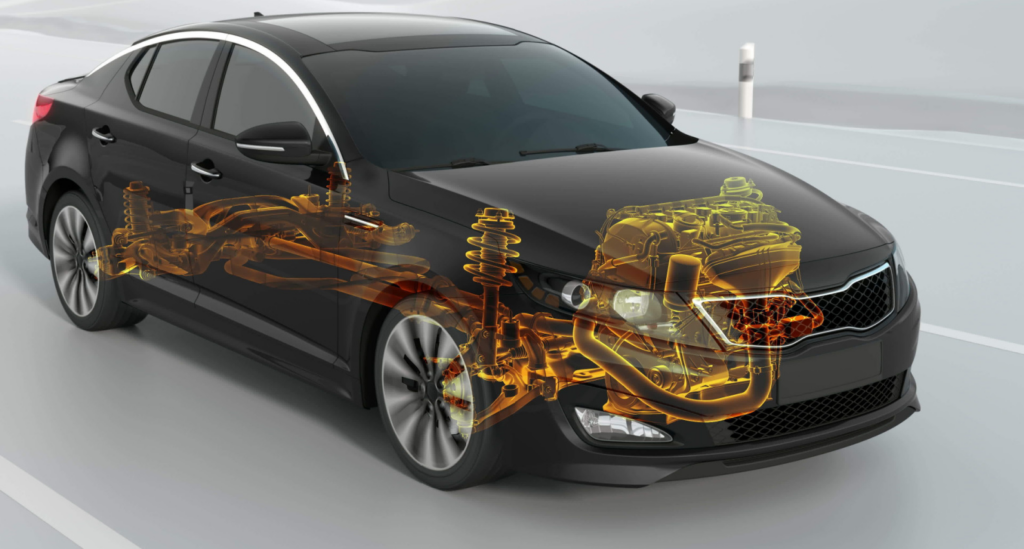

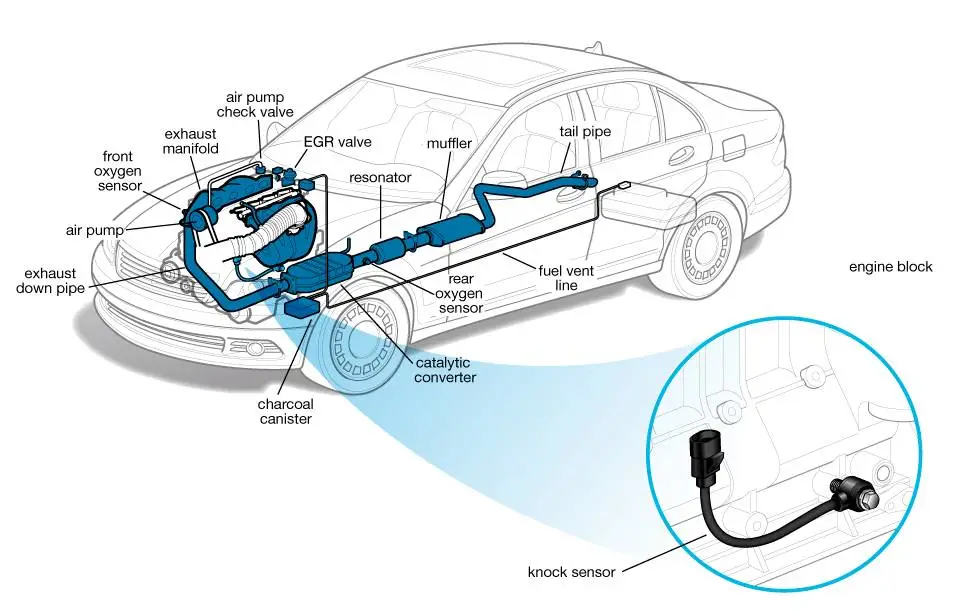

How Knock Sensors Work

Modern engines are equipped with knock sensors to detect and prevent detonation.

- These sensors use piezoelectric elements to monitor engine vibrations and detect the frequency of knock.

- When knock is detected, the engine control unit (ECU) retards ignition timing, reducing cylinder pressure and preventing damage.

- Some advanced ECUs can also adjust fuel mixture and boost pressure to further mitigate knock.

Pre-Ignition

Pre-ignition occurs when the air-fuel mixture ignites before the spark plug fires. Unlike detonation, which is an uncontrolled explosion occurring after the spark plug ignites the mixture, pre-ignition happens prematurely, usually due to excessive heat in the combustion chamber. This premature ignition disrupts the engine’s precise timing, leading to severe consequences, including excessive pressure buildup and engine damage.

Causes of Pre-Ignition

Hot Spots in the Combustion Chamber

Certain engine components can become excessively hot and act as an unintended ignition source. Carbon deposits, which build up over time, can retain heat and ignite the mixture. Similarly, spark plugs that are too hot for the application can glow red-hot and prematurely ignite fuel. Other metal surfaces, such as a sharp edge on a valve or piston, can also act as ignition points.

Overheated Engine Components

Engines operating at extreme temperatures are more susceptible to pre-ignition. Overheated valves, pistons, and cylinder heads can exceed the auto-ignition temperature of the fuel-air mixture, leading to premature combustion. Insufficient cooling, poor heat dissipation, or prolonged high-load operation can exacerbate this risk.

Oil Contamination in the Combustion Chamber

When oil seeps into the combustion chamber, it can lower the mixture’s auto-ignition temperature. The presence of oil droplets creates unpredictable burning patterns, increasing the likelihood of pre-ignition.

Effects of Pre-Ignition

Severe Engine Damage

Pre-ignition can lead to some of the most destructive engine failures. The uncontrolled explosion exerts extreme forces on the pistons and connecting rods, sometimes melting piston crowns, cracking cylinder walls, or even punching holes through engine components. The rapid rise in temperature and pressure can result in total engine failure within seconds.

Uncontrolled Combustion Events

Unlike normal combustion, where ignition occurs in a controlled manner, pre-ignition leads to erratic burning that is difficult to predict or manage. This disrupts power delivery, reduces efficiency, and makes tuning an engine safely much more difficult. If left unchecked, these unpredictable explosions can lead to detonation, compounding the damage further.

Prevention and Safe Tuning

Avoiding pre-ignition requires careful attention to tuning, maintenance, and overall engine health. Here’s how to minimize the risk and keep your engine running reliably:

Fuel Quality and Selection

Using the correct octane rating is one of the simplest yet most effective ways to prevent knock. High-performance engines often require higher octane fuel, which resists premature ignition. High-quality fuel with proper detergents also helps minimize carbon buildup, reducing the risk of hot spots.

Optimizing Spark Timing

Modern engines utilize knock sensors and ECU-controlled timing adjustments to optimize spark timing. By fine-tuning ignition timing, tuners can extract maximum power without pushing the engine into dangerous conditions. Timing that is too advanced can contribute to knock, while overly retarded timing can lead to inefficient combustion and excessive heat buildup.

Maintaining a Proper Air-Fuel Ratio (AFR)

A lean fuel mixture can elevate combustion temperatures, increasing the likelihood of pre-ignition. Wideband oxygen sensors allow for precise AFR monitoring, ensuring the mixture remains within safe limits. Keeping the engine well-tuned with an optimal fuel map is key to longevity.

Cooling System Efficiency

A well-maintained cooling system prevents engine components from overheating. High-performance radiators, properly functioning thermostats, and efficient cooling fans help dissipate excess heat, reducing the chances of hot spots forming inside the combustion chamber.

Regular Engine Maintenanceя

Routine maintenance is critical for preventing pre-ignition. Carbon deposits should be regularly cleaned using fuel additives or mechanical cleaning methods. Spark plugs should be inspected and replaced based on manufacturer recommendations, ensuring they are the correct heat range for the engine’s operating conditions.

Data Logging and Engine Monitoring

Modern tuning relies heavily on data logging tools, including OBD-II scanners and advanced tuning software. By monitoring knock events, cylinder temperatures, and timing advance, tuners can detect potential issues before they lead to catastrophic failure.

Safe Tuning Practices

When tuning, always start with conservative parameters and gradually increase power levels while monitoring for signs of knock. It is crucial to tune in a controlled environment, using dynos or closed circuits rather than pushing limits on public roads. Monitoring real-time engine data is essential for making safe adjustments.

The Importance of Professional Tuning

While self-tuning is tempting, improper adjustments can quickly lead to engine damage. Professional tuners have the experience, tools, and knowledge to optimize engine performance safely. Knowing when to seek expert help can make the difference between a well-performing engine and one that fails prematurely.

Advanced Topics

For those seeking additional knock-prevention measures, several advanced technologies are available:

- Water-Methanol Injection: This system injects a water-methanol mixture into the intake stream, cooling the combustion charge and reducing the likelihood of pre-ignition.

- Direct Injection Considerations: Direct-injected engines have unique combustion characteristics that affect knock resistance, requiring precise fuel delivery control.

- Advanced Knock Detection: Technologies like in-cylinder pressure sensors offer real-time monitoring of combustion dynamics, providing valuable insights for tuning and diagnostics.

Conclusion

Knock poses a significant threat to engine reliability and performance. Understanding the causes, effects, and preventive measures is crucial for ensuring long-term engine health. Proper fuel selection, precise tuning, effective cooling, and routine maintenance all play a role in keeping an engine safe from premature combustion events.

Safe tuning and professional expertise are indispensable in pushing an engine to its limits without risking failure. By approaching engine modifications with caution and a deep understanding of knock prevention, enthusiasts can achieve both power and longevity in their builds. Stay informed, prioritize safety, and never underestimate the value of proper engine care.