Whether you’re a car lover who’s into appearance and competition, or if you simply like custom wheels and are interested in learning more about them, this is the place to be. There’s no question that you recall those savage custom wheels on a passing car or truck. Clean, sharp custom built wheels attract attention. However, before you start on your quest for that ideal set of custom wheels, read this article and learn everything you need to know about custom wheels and how to select the perfect set for your automobile.

Custom Wheel Defined & Basics

What is a Custom Wheel?

A wheel is a unit that includes both the steel rim and the tire. When vehicle manufacturer’s original or standard wheels are replaced with aftermarket wheels, the result is called “Custom Wheels.” You may think of custom wheels as upgraded or non-stock wheels that add a classic, sporty, or stylish design to a car or truck.

What Is A Custom Wheel Made Up Of?

The majority of custom wheels are now manufactured from a molten aluminum mold, resulting in cast aluminum alloy as the final product. Steel, on the other hand, is still utilized in wheel manufacturing. When compared to steel, aluminum has a higher strength-to-weight ratio, which means it is lighter and stronger. This means that aluminum wheels are light and strong. But alloy custom wheels, unlike steel wheels, may be pricey. As a result, the type of material used to create custom wheels is determined by weight, price, strength, and durability.

What kind of finishes are there?

Custom wheels are available in a variety of finishes, including chrome, polished, and painted.

- Chrome

Chrome, in general, is an electroplating process that involves the application of many layers of metals, most often nickel or copper, followed by chrome plating. Wheel makers are now utilizing a new technique known as Physical Vapor Deposition (PVD) Chrome, which uses a clear topcoat to protect PVD chrome wheels. Custom chrome wheels have an excellent sheen and mirror-like finish when completed.

- Polished

Custom wheels with polished rims are manufactured by smoothening, buffing, and polishing the raw aluminum on a rim. The polished surface serves as a protective covering for the raw aluminum on the wheel, protecting it from weather and scratches.

- Custom Painted

Custom color wheels, also known as custom painted wheels, are available in any paint finish. The most frequent color is generally used as a single or combination of colors to create contrast with the car’s primary color, as an accent to a two-toned truck or automobile, or to match the car’s or truck’s color.

Specific Interest Involving Custom Wheels

American Racing Wheels

As the name suggests, if you are into racing, you might opt for these racing custom wheels because of their lightweight and durability in racing cars.

Drag Racing

Custom wheels for drag racing are chosen based on their width, which improves traction and grip on the road.

Rally

Street rally, which is not authorized, has gained popularity in recent years. If you enjoy street racing, you may want to look into a set of custom wheels made of aluminum or a high magnesium prime version of aluminum alloy because of their light weight, strength, and longevity.

Off-Road Use

Steel-made custom wheels would be the ideal option for those who want to experience off-road driving. Steel wheels are malleable and thus more susceptible to bending, but they are also stronger and nearly impossible to break. As a result, if you get yourself into trouble while driving off-road in some challenging terrain, a hammer can assist you in restoring them back to form and resuming travel.

Street Driving

If you value appearances and aesthetics, street-driving custom wheels for their visual appeal and weight are the way to go. A genuinely sick collection of custom wheels will most certainly get you the attention and recognition they seek, guaranteed to draw notice from others.

Trucking

You could also choose to make your own custom truck wheels if you’re enthusiastic about trucks. In addition to improving the look of your vehicle, installing custom wheels may help raise the value of your truck and, hence, increase its resale price.

Touring, Auto Crossing

If you’re a competitive enthusiast, choose these custom wheels since they provide greater cornering performance because of their width and weight, which encourages better handling.

Multi-Purpose

Finally, if you are both an appearance- or competition-oriented sports fan, multi-purpose custom wheels are a fantastic option. Multi-purpose bespoke wheels might be built to suit your requirements for width, weight, visual appeal, and strength by combining several wheelsets.

Wheel Offset

Choosing the ideal set of standard or custom wheels for your car or truck can be challenging. Essentially, in order to make a decision that fits your appearance or competition needs, you must first understand the fundamentals and evaluate numerous aspects or technical specifications of wheels. The following are some of the characteristics and requirements that you should know about before purchasing new wheels: Wheel Diameter, Wheel Offset, Wheel Width, Plus-Sizing, Staggered Wheel Fitment, Backspacing, Center Bore Centering Rings, Hub Centric vs. Lug Centric Wheels, Wheel Spacers and Adapters, Bolt PatternPitch Circle Diameter, and TPMS Sensors.

The overview below serves as a practical tutorial on how to comprehend each of these aspects and parameters.

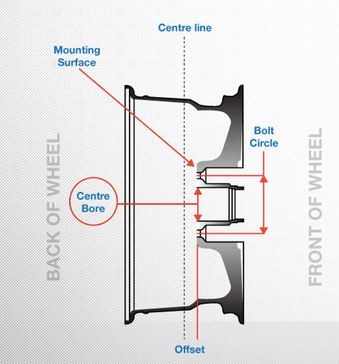

What Is Offset?

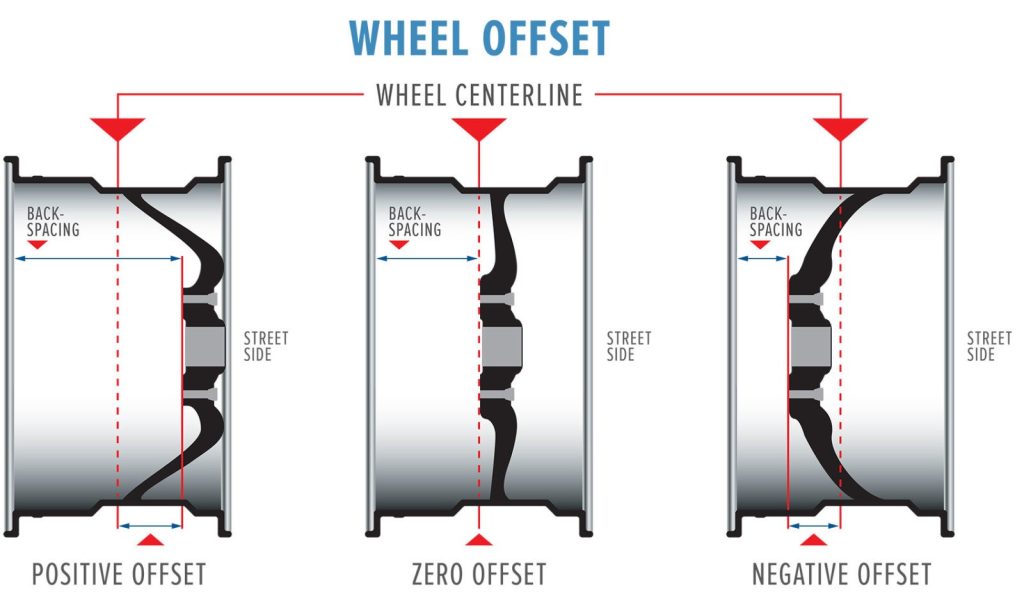

Offset is the distance between a car’s actual centerline and its hub mounting surface. The offset is normally zero, negative, or positive. When the hub mounting surface lines up with the rim centerline, the offset is known as zero. Finally, when the rear of the wheel and the hub mounting surface are closer together than usual, resulting in a centerline that is further outboard than the mounting surface, it is considered to have a negative offset (low offset).

Wheels that are classified as “deep-dish” have a negative offset by definition. Finally, the visible side of the wheel (wheel face) and the hub mounting surface sit closer to each other, with the mounting surface sticking out farther than the rim centerline, resulting in a positive offset.

What Impact On a Vehicle Does a Wheel Offset Have?

Standard automobile and truck wheels are designed with an original offset based on the manufacturer’s specifications. Using custom wheels, on the other hand, might result in a change in wheel offset, which can affect vehicle performance. If the new custom wheels’ offset differs significantly from the initial offset, wheel bearings wear out faster owing to the influence on bearing load.

Such problems include clearance issues between the fender and the tire. Furthermore, when cornering at high speeds or traveling over bumps, tires with a significant offset variation tend to rub on body panels, resulting in increased wheel wear and tear.

Wheel Diameter

Wheel Diameter Defined

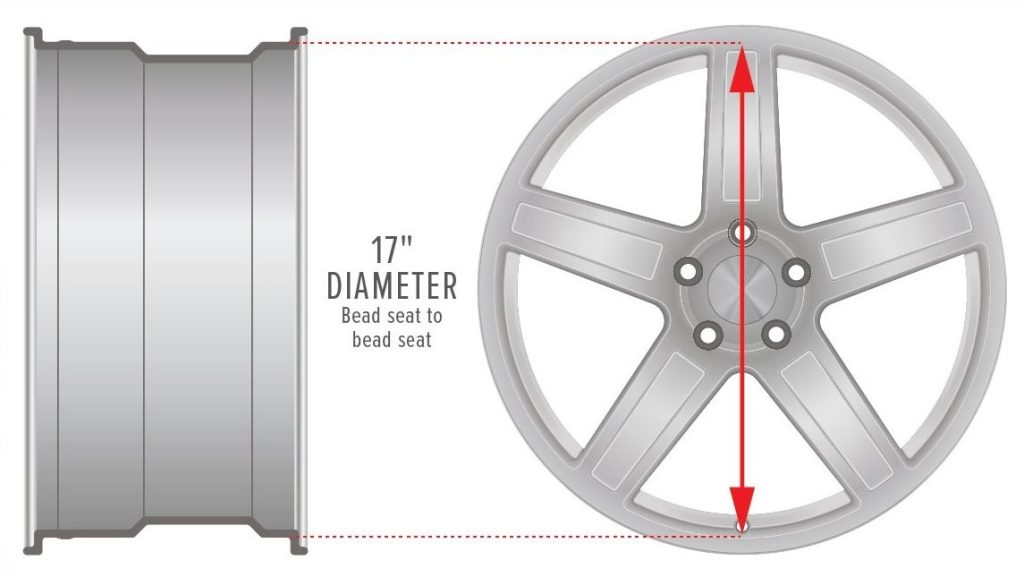

Diameter is the most common and significant wheel dimension when it comes to custom wheels or aftermarket wheels. For most trucks and cars, popular aftermarket wheels and original equipment manufacturer (OEM) designs have for years followed a common wheel size of 14″ and 15″. Today, even 34″ custom rims have been produced, suggesting that there is no limit to aftermarket wheels.

The distance between one point where the tire seals to the rim (bead-seating point) and another, but along the center of the rim, is used to determine wheel diameter. The visible wheel’s surface area rises with an increase in rim diameter as you would expect. Who knows what the future holds for custom wheel diameters as technology advances and people strive for their objectives?

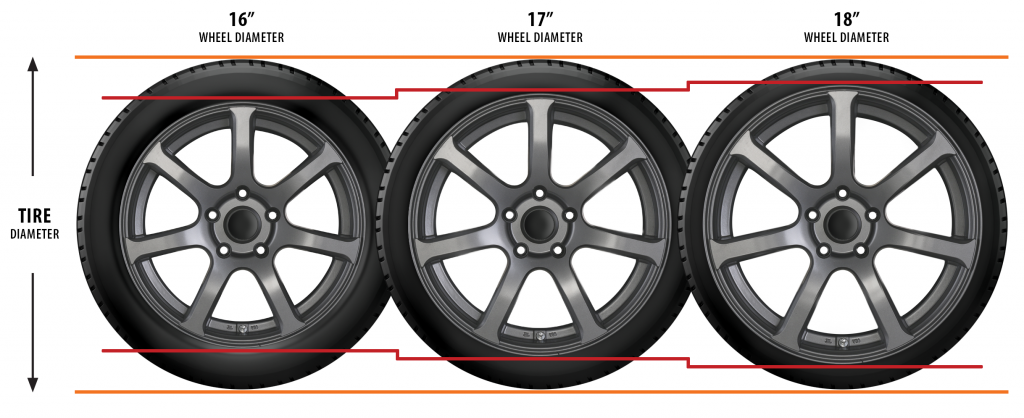

Plus-Sizing Defined

Plus-sizing is the practice of increasing wheel diameter. When you need to bypass the requirement to change your car or truck, retain factory braking and handling, and avoid incorrect speedometer readings, this technique is essential. A “plus one” upgrade refers to a one-inch diameter increase, whereas a “plus two” upgrade refers to a two-inch diameter increase on the wheel, according to standard sizing.

According to the preceding definition of diameter, it is critical to comprehend that as the diameter of a wheel increases, the tire’s sidewall (aspect ratio) must be reduced proportionally if the same approximate diameter of tire is required. The aspect ratio is defined as the height of the tire’s sidewall as a percentage of its width (defined in the next section).

A tire with a width of 210mm and a 60 aspect ratio on a 15″ rim, for example, may be plus-sized with 220/50R16 (plus one upgrade) & rim component (plus one upgrade) such that the total diameter of the tire remains approximately equal.

Why Plus-Size?

Plus-sizing improves your car or truck’s aftermarket wheels’ sharper reflexes. It also helps you avoid modifying your automobile or truck, as well as maintaining factory brakes and handling, as well as avoiding incorrect speedometer readings. This is due to stiffer and less flexible shorter sides of low-profile tires. Again, lower-profile tires respond with significantly less effort and drag because to quick tire reactivity when the steering wheel is turned.

The rim width should increase proportionately with the wheel diameter, since this is a natural consequence of an increase in wheel size. This allows for bigger tires and, as a result, improved traction because there is more rubber in touch with the road. Furthermore, by reducing the apparent dull black tire size, the technique enhances the beauty and appearance of the rims.

Drawbacks of Plus-Sizing?

Unfortunately, there are several drawbacks to plus-sizing. To begin with, wheel cushioning diminishes as the sidewalls get shorter and shorter. This implies that the danger of tire damage rises three times as much when driving on bad roads, especially when the wheel hits a pothole. A single blister bubble that may develop on the sidewall of a tire following a hard hit on a rock or a pothole might cause internal damage and even blow out, in some cases.

Furthermore, the weight of the wheel increases as the diameter of the wheel increases. As you would expect, a greater rotational mass necessitates more horsepower, which means you may run into budget issues owing to increased fuel consumption. When decelerating, you’ll also need more braking power. Finally, because of the high inertia associated with an increase in weight of the unsprung component, shock absorbers and springs become less responsive.

Lifted Trucks & The Need For Larger Diameter Tires

The interesting aspect of lifted trucks is that being raised from the ground does not affect how they ride. Typically, while factory suspension geometry and alignment are kept, lifting a truck up increases tire clearance allowing for larger diameter wheels. Larger wheel fittings are popular off-roading modifications for truck enthusiasts, allowing them to lift the truck higher from the ground and provide greater ground clearance.

Why Do Larger Tires Cause Incorrect Speedometer Readings?

Increasing the diameter of a wheel generally implies that precise speedometer readings are disrupted. Because of a larger circumference, the rotations of a tire decrease with an increase in diameter. The speedometer accounts for this by assuming that slower rotation means lower speed, but the car or truck would really be moving at a greater rate.

When your speedometer is displaying an incorrect reading because it doesn’t match the true speed of your car or truck, you are putting yourself and others at risk. For example, if you cruise at a higher speed than indicated by your speedometer, you can easily go above the limit, putting yourself and others in danger.

Inaccurate speedometer readings, on the other hand, can be adjusted. Manufacturers have now produced portable digital controllers that may talk to your truck’s or car’s onboard computer. Often plugged into any OBDII port, the original and replacement tire sizes are fed such that the digital controller can rectify the issue and provide your speedometer with the correct readings based on the original manufacturer’s design.

Wheel Width

What It Is & How Do You Measure?

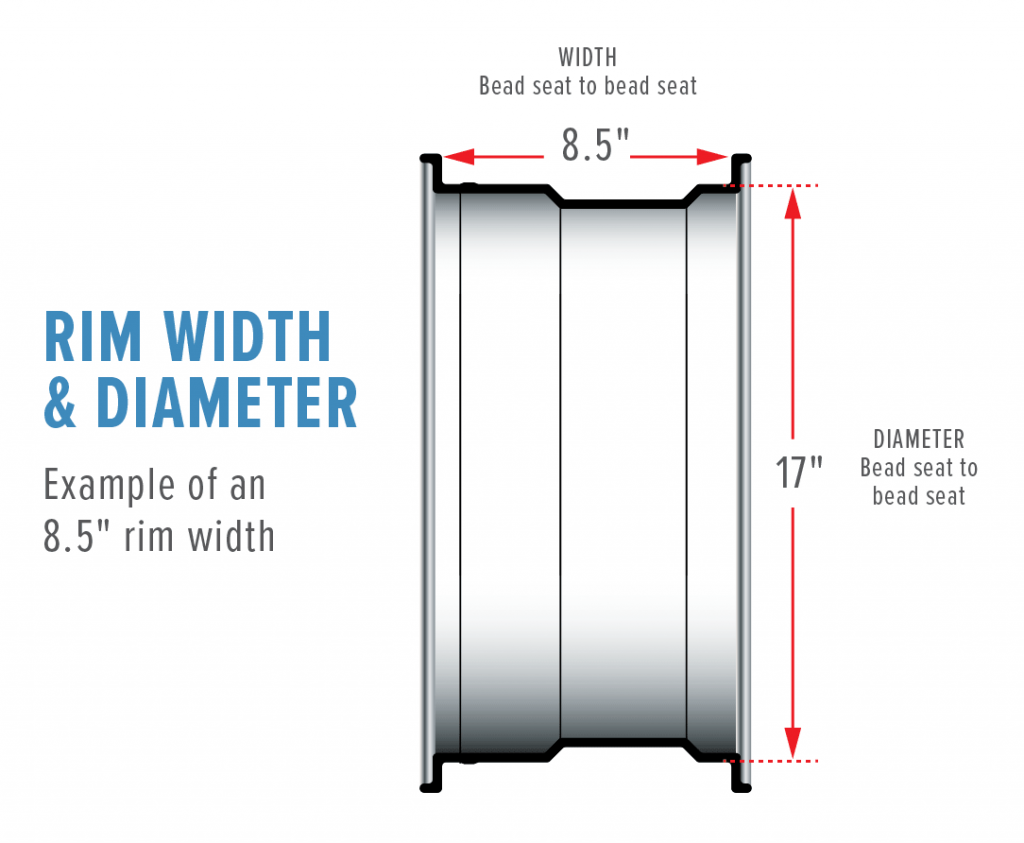

The wheel width is one of the most important wheel dimensions to consider when sizing the proper tire. The distance between two bead seating points across the rim is used to calculate wheel breadth, as shown in the illustration below. With the need for broader ties, wheel breadth has likewise risen.

The preceding means aftermarket wheel producers build wheels that are sized in accordance with the tire to be installed. However, when considering the rim width from narrowest to widest, the real tire width could differ by up to an inch in some cases. As a result, custom wheelmakers must pay close attention to rim width.

Does Running a Wider Wheel Make Sense?

When you use wider wheels, traction and grip improve owing to a larger rubber surface area in contact with the road. Furthermore, because the bigger surface area of the tires in touch with the ground, wider custom wheels are more efficient when it comes to braking.

Custom wheels, on the other hand, weigh more as their width increases. As a result of an increase in rotational mass and higher rolling resistance caused by greater horsepower, fuel usage rises. When compared to narrower tires, because wider tires are less efficient in creating a running path, they lose grip when running in wet and snowy conditions. Furthermore, as opposed to narrow tires, broader wheels are less able to avoid the vehicle from swinging sideways due to road ruts.

Staggered Wheels

With the increasing popularity of custom wheels, vehicle wheel fitment has evolved as well. Usually, cars and trucks have frequently utilized a square wheel fitment, which is made up of a typical set of four identical wheels. Some cars and trucks, on the other hand, employ front and rear wheel pairs that are different in size.

A staggered wheel fitting is one in which the rear wheels of a car or truck are wider or larger than the front ones. Rear-wheel-drive automobiles have typically utilized this type of traction because larger and wider wheels provide more grip at the back. Because rear grip prevents the rear from flying off, such a setup significantly improves stability when accelerating out of a turn.

Backspacing & the Center Bore

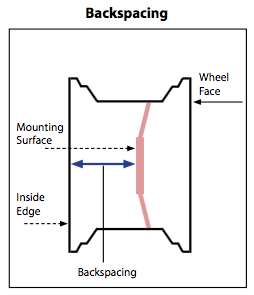

Backspacing Defined?

Backspacing is the distance between the hub mounting surface of a wheel and the rim’s inner edge (the outermost edge of a wheel’s backside). The backspace may be measured by placing the wheel on its face down and looking at the backside. Welding the center of a made-to-order rim to a preassembled rim can cause problems with centering, so some makers weld the center into the wheel in a certain location to allow for proper fender fitting.

The distance between the true centerline of a rim and its hub mounting surface (where the wheel is bolted to the vehicle) is called wheel offset. As a result, both the backspace and offset on a replacement wheel must be set properly to ensure that the tire and rim components fit properly inside the fitting space. When the hub mounting surface is aligned with the tire’s rim centerline (zero offset as described herein), the backspace must be positioned within half of the wheel width for a successful wheel replacement.

Center Bore Defined (i.e., Center Holes)?

Center bore, as the terms “center” and “bore” suggest, refers to the hole/bore that is generally milled and cut at the wheel’s center and intended to cover the flange extending from the wheel’s hub. In most cases, the bore ensures that the flange places the wheel in the middle while lugs are tightened such that it does not fly off. In most situations, vehicle manufacturers have developed unique flange designs to fit their own specifications, so there are no standard wheel hub flanges for custom rim makers to follow.

The Necessity of Centering Rings

When it comes to designing custom wheels, centering rings are extremely important. Aftermarket wheel makers find the difficulty and inefficiency of producing a custom wheel that fits only a specific automobile inconceivable. As a result, to ensure that a custom rim can be fitted to as many cars and trucks as possible, the center bore discussed in the previous sections is usually machined and cut to be large enough to accommodate any hub flange size.

However, to come up with a fit that is tight and specific to a given car or truck, centering rings, such as the ones shown in the image below, are used. There is a wide range of centering rings with a center bore aligning with specific flange sizes. Usually, centering rings are designed to fill the space between a rim’s center bore and the wheel hub. This means that centering rings have to be selected very carefully because they can affect the handling of a car or truck.

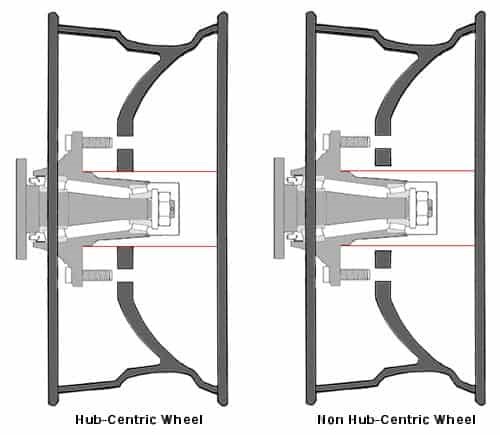

Difference Between Hub-Centric & Lug Centric

The term “centric” derives from the state of being “in or at the center.” In many cases, custom wheel manufacturers make wheels that do not center on the hub flange. As the wheel assembly tightens to the flange during mounting, wheels that do not center by themselves have to be centered on lug studs or bolts. For this reason, they are called non-hub-centric wheels and, consequently, “lug-centric.” During mounting, it is wrong to tighten lug centric wheels with the wheels bearing the car or truck’s weight because it increases the risk of vibration and run-out.

Wheel Bolt Patterns

Wheel Bolt Patterns Defined?

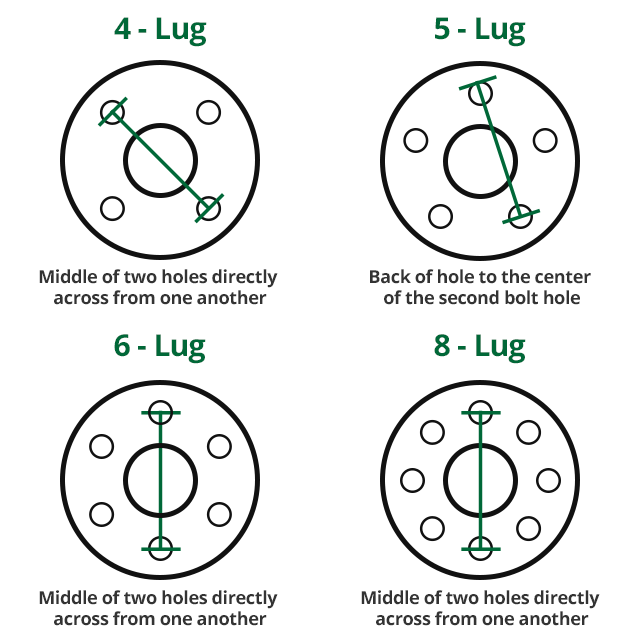

When it comes to securing wheels on the hub, the configuration of the bolts on the hub is critical and described as the bolt pattern. Usually, lug bolts thread to holes and lug nuts fasten to studs on the hub to ensure that the wheel is secured. A bolt pattern is often denoted as “A × B,” where A represents the count of holes or studs on the hub and the distance between two specified bolts. For example, if a car or truck has a “5 × 4.75” bolt pattern, then it means that it has five-lug (five bolts and five nuts per wheel) hubs and the distance from the backside of the top hole to the center of the opposite hole is 4.75 inches.

As shown, the bolt pattern varies with the number of lugs and, consequently, the holes and studs. However, just like the distance between adjacent holes or studs varies, the count of holes or studs on hubs of different vehicles also varies. For this reason, not every car or truck with six studs can be fitted with a wheel that has six holes. Therefore, to confirm a specific bolt pattern fit for your car or truck, you should utilize a bolt pattern gauge to avoid reading errors in some patterns, such as a five-lug bolt pattern.

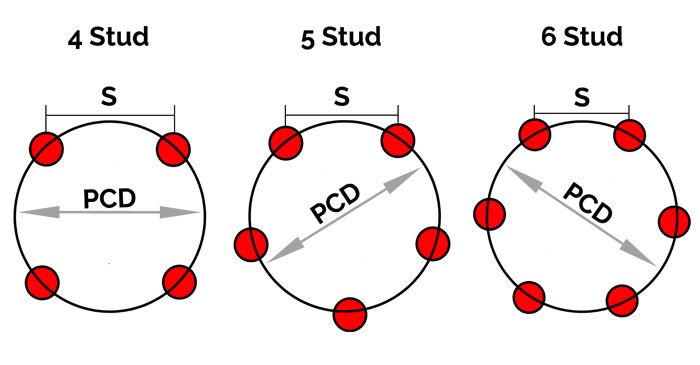

PCD (Pitch Circle Diameter)

Abbreviated as PCD, the pitch circle diameter refers to the diameter of a virtual circle passing through the center of all-wheel rim holes, lug bolts, or studs. To determine this length, the distance between the center points of two lug holes is measured.

Wheel Spacers, Wheel Adapters.

When Do You Need Wheel Spacers?

Aftermarket wheel manufacturers also design simple but vital round metal plates used for correcting problems that arise with wheel backspacing and offsetting. For instance, they help relocate a wheel to a negative offset (to a more outboard location) if, due to an offset effect, a wheel has a positive offset (a more inboard location). These round metal plates are known as wheel spacers and are mounted on the wheel hub assembly to correct these issues.

In most cases, instead of purchasing new components because of issues caused by offset or the use of wider tires, you may opt for wheel spacers because they reduce the effort and expense of fitting your car or truck with custom wheels. Furthermore, if you need extra space for additional suspension upgrades, you may need to use wheel spacers.

When Do You Need Wheel Adapters?

Technically speaking, wheel adapters can be viewed as an upgrade for wheel spacers. While they allow you to create a more negative offset, wheel adapters are designed to enable and facilitate a change of the bolt pattern as well. This means that you do not have to rely on a pattern matching the OEM one when choosing your aftermarket custom wheels. Accordingly, a change in the bolt pattern also allows you to use a custom wheel with a totally varying PCD because of the change in the number of studs and holes.

Are There Disadvantages Associated With Spacers Or Adapters?

However, there are shortcomings with wheel spacers and wheel adapters. Most of these issues arise with creating a more negative offset, which interferes with the original design intended by vehicle engineers and manufacturers. As customs wheels move significantly outboard than the original design, the suspension geometry and balance of a car or design are negatively impacted.

For instance, a significantly larger negative offset causes an uneven distribution of the load angle, which, as mentioned in section 3(b), may cause wheel bearings to wear out at a faster rate because of the negative effect created on wheel bearings load. These shortcomings also include increased steering and handling difficulties because of adverse changes in alignment specifications.

TPMS (Tire Pressure Monitoring System) Sensors

The initials TPMS refer to the Tire Pressure Monitoring System, which comprises an onboard computer used to read radio signals received from tire stem sensors mounting on each wheel inside the tire. Since 2008, Congress passed the 49 CFR § 571.138 – Standard No. 138 act, which required the installation of TPMS in all vehicles sold in the United States henceforth.

This means you have to figure out how to incorporate TPMS in your new custom wheels because this is a law requirement. You’ll need to either transfer or install a new TPMS component in your newly-acquired set of custom wheels. Because the TMPS often wears out, you’d probably want to purchase a new one altogether if you’ve been with the old one for a long time.

Note that some manufacturers, such as Tesla (no relation here, of course), will have stock wheels with the TPMS already mounted, which do not need to be adjusted or calibrated. Also, note that TPMS is purchased in whole sets due to the standardized manufacturer—what this means is that you will not be able just to purchase a stem or some other solo component, but rather, you are buying them as a kit overall.

Conclusion

Specially made for you, our readers, this article is designed to act as a hands-on guide to understanding the ABCs of custom wheels. Are you looking for a sleek set of customized rims for your car or truck? This article is a one-stop shop for ensuring that you are fully equipped and knowledgeable of all wheel parameters, components, and specs you need to know so that you can make your best decision when choosing that perfect set of custom rims you’ve always desired to purchase and give your car or truck a breath-taking new look.

Dreaming to Roll? We Make It Happen!